Product

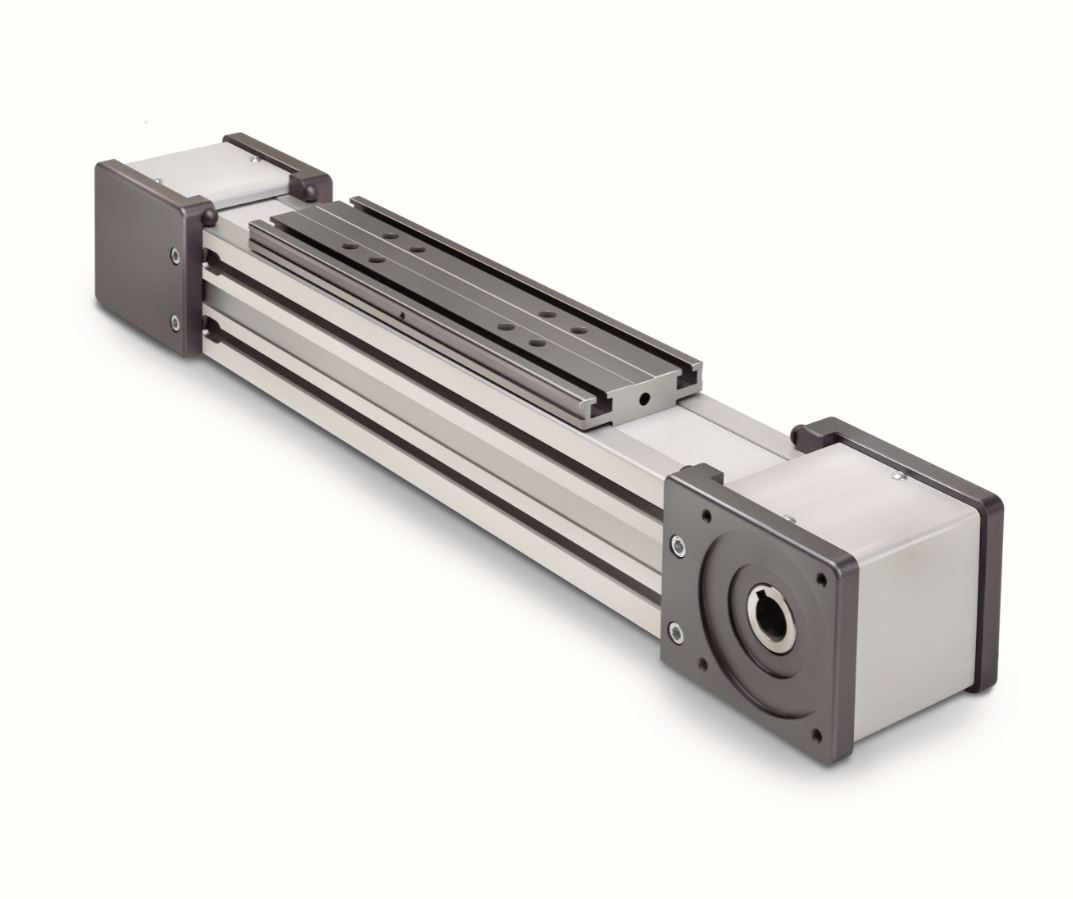

Module linéaire AGORA Technique

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Threadless ball screws The threadless ball screw is designed mainly for handling mechanisms of manipulators and transporting devices, which require effective transition of the rotary motion to linear without the preference of high rigidity and load capacity, but with the requirement for simplicity, easy maintenance and easy production. Screw thread is produced only in the nut and the transition of the load is provided only through the balls in the nut and the smooth cylindrical surface of the shaft. The principle is based on the elastic deformation of the surface of the hardened and ground shaft caused during the rolling of the preloaded balls guided in the inner screw thread of the nut. In this application it is possible to use the slippage of the nut on the shaft after exceeding certain axial force as a safety element. The nut continues in its motion in the original direction after the decrease of the load, or the current increase causes drive disconnection. Threadless ball screws : www.ks-kurim.cz/en/additional-assortment/threadless-ball-screws/

-

High-efficiency ball screws These ball screws are designed for applications requiring high efficiency of the transmission. They are used especially in machine tools and other equipment which meet the requirements for low energy consumption, as well as where high efficiency is required in order to eliminate heat sources or when an optimal ball screw drive is needed. The high efficiency is achieved by an accurate thread profile ground section, by precise geometry of the groove and alternatively by the use of ceramic balls in the recirculation system. These ball screws are produced in the precision classes IT1 to IT5. For this type of ball screws the following nut types are available: All types of nuts, non-preloaded nuts with backlash up to 0.05 mmCharacteristics: Application of ceramic balls, special gothic thread profile Precise positioning ground ball screws Standard geometric and working accuracy according to DIN ISO 3408 Reduced Tp values (usually by 15 to 20% against the standard)Technical parameters: Diameters from 12 to 63 mm Recommended pitch up to 10 mm Precision classes from IT1 to IT5 Do×n = 80.000, efficiency 96–98% (according to thread pitch and lubricant) Minimum strength of the shaft material Rm= 650MPa, functional surfaces of the shaft and nut hardened to 58–60HRC Working temperature -20 to +60°C A lubricant with reduced noise is recommended for a smooth runApplications: Energy saving machine tools Laboratory and measuring equipment Aerospace industry These ball screws have no separate technical parameter table and they can be supplied with different nut units (A, AP, A+A, AP+A, APR). Example of designation: K63x10 – 4/AP HE/2 (ball screw with diameter 63 mm and pitch 10 mm, 4 working threads, single non-preloaded nut with flange, high efficiency design, flange type 2) High-efficiency ball screws : www.ks-kurim.cz/en/ball-screws/high-efficiency-ball-screws/

-

Linear actuators The linear actuator provides drive controlled linear motion within the range of the working stroke, thus replacing hydraulic cylinders. It converts the rotary motion into linear actuation by the use of a ball screw with minimum transition efficiency 95%, stroke range 150–600 mm upon axial load from 12.5 to 25kN. The actuation speed can be regulated or set by a suitable selection of the pitch of the used ball screw in relation to the used electric motor. Linear actuators : www.ks-kurim.cz/en/additional-assortment/linear-actuators/

-